Philosophy

Caltest’s philosophy is to generate scientifically sound, legally defensible data of known quality. The implementation of our QA plan puts a strong emphasis on traceability of the data, assuring that sufficient detail is recorded and accessible for future review. Caltest is certified under the National Environmental Laboratory Accreditation Program (NELAP), and the State of California Environmental Lab Accreditation Program (ELAP). Compliance with these programs, and the related audits for these certifications add to the defensibility and integrity of the data we produce. Our goal is to provide method compliant data that is suitable for the purpose for which the sample was collected. SOPs are used for all processes in the lab. They are reviewed and updated by our QAO. A complete copy of our Quality Assurance Manual describing the protocols and procedures we use is available upon request.

Data Integrity

All staff at Caltest signs and abides by an ethics and integrity agreement regarding data handling practices, a confidentiality agreement, and an agreement to abide by the protocols and policies of the Caltest Quality Assurance Manual, and the employee handbook. Monthly staff meetings re-iterate the critical importance of maintaining the highest standards of integrity with regards to our data.

Caltest’s criteria for acceptance of new work require consulting with the analytical staff to confirm the labs’ ability to take in the proposed work and client specific QC criteria. This policy has been a cornerstone of not setting the lab up for failure.

Another key component to minimize the potential for fraud is controlling the sales efforts. The general manager and project managers coordinate all new work with the lab director and department coordinators. No one is paid sales commissions at Caltest.

Our targets for increased sales are long term, stable clients requiring higher levels of commitment and service than typical off the street commercial work. This type of client appreciates the service our staff provides, and in turn, allows us to continue on the plan of steady manageable growth as opposed to the ups and downs of commercial or governmental short term project work with high sample loads in short periods of time.

Quality Assurance:

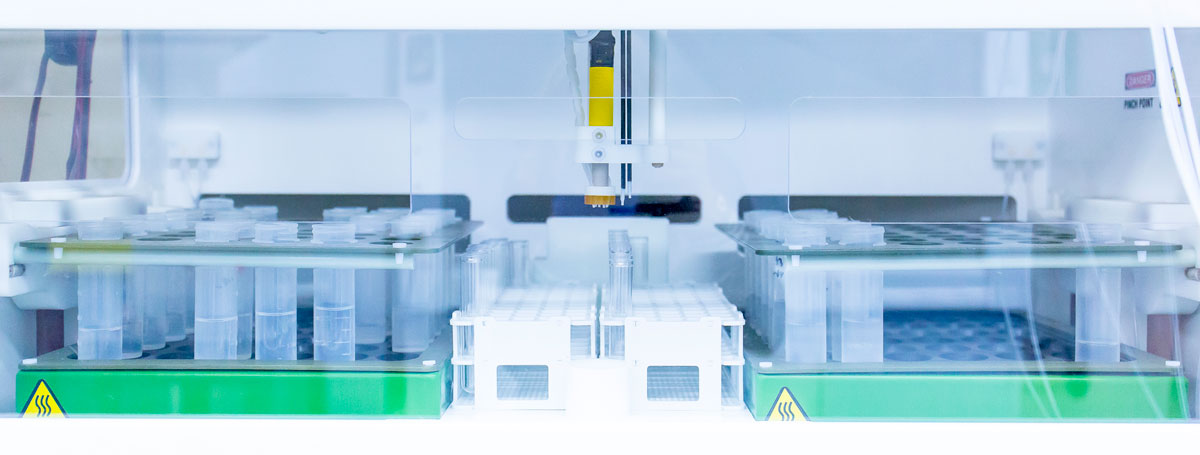

Each analysis starts off with a calibration curve, which must meet criteria before proceeding with the analyses. Each analysis has measures of accuracy and precision, as well as monitoring of background contamination through analysis of method and instrument blanks.

Routine QC reports include a method blank, laboratory control sample, matrix spike and duplicate analyses. In addition to the daily routine analyses for quality, Caltest participates in programmatic QC for the National Environmental Laboratory Accreditation Program (NELAP), U.S. Army Corps of Engineers, and specific commercial and federal clients.

When samples are received they are given unique identifying numbers before being made available to the lab staff in the central refrigerators. Lab numbers are tracked throughout the entire process. Once an analysis is complete, almost all of the lab results are automatically downloaded into our LIMS system eliminating the chance of data recording errors. Dilution factors are applied in the download system as entered by the analyst at the time of the dilution. If a project manager or a client desires a recheck of the analyses, calculations and data entry are rechecked, and finally if no error is found, three additional aliquots of the sample are prepared for analyses to compare with the original value.

All containers purchased for use as sample containers are pre analyzed by the vendor or analyzed by Caltest by lot to ensure suitability with the requirements the containers will be used for.

In the event of equipment failure, most of Caltest’s instruments have redundant backup. We have service contracts to speed the time of repair, and expedite parts and service with overnight service.