Oil and Grease Analysis

Oil and grease includes fats, oils, waxes, and other related constituents found in water, generally wastewater. If these compounds are not removed before discharge of treated wastewater, oil and grease can interfere with biological life in surface waters and create unsightly films.

Fats and oils are contributed to domestic wastewater in butter, lard, margarine, and vegetable fats and oils. Fats are also commonly found in meats, in the germinal area of cereals, in seeds, in nuts, and in certain fruits. The low solubility of fats and oils reduces their rate of microbial degradation.

Kerosene, lubricating, and road oils are derived from petroleum and coal tar and contain essentially carbon and hydrogen. These oils can reach sewers in considerable volume from shops, garages, and streets. The mineral oils coat surfaces to a greater extent than fats, oils, and soaps, and the particles interfere with biological action and cause maintenance problems.

EPA method 1664 uses n-hexane as the extraction solvent for Oil and Grease and other extractable material that is not adsorbed by silica gel in surface and saline waters, and industrial and domestic aqueous waste. N-hexane extracts non-volatile hydrocarbons, vegetable oils, animal fats, waxes, soaps, greases, and related materials. Petroleum fuels and gasoline through Diesel #2 fuel oil are also extracted by n-hexane; however, they may be partially lost due to solvent removal operations (materials that volatilize below 85°C). Some crude and heavy fuel oils contain materials that are not soluble in n-hexane, resulting in low recoveries.

The previous accepted methods, EPA 413.1 and 418.1, used Freon (CFC-113) as the extraction solvent. N-Hexane was chosen as the alternate solvent because it most closely approximated the results of the Freon extractions. Total Petroleum Hydrocarbons (TPH, or the hydrocarbon portion of Oil and Grease) was determined using an Infrared Spectrophotometer, and with the updated method (EPA 1664) TPH can be determined gravimetrically. Unfortunately, EPA 1664 is less robust compared to the previous methods for TPH because the volatile compounds are lost when the solvent is evaporated.

The oil and grease method requires samples to be collected in glass, and the bottle must not be pre-rinsed with sample before collection. Oil and Grease compounds are hydrophobic and prefer to associate with the glass container rather than the water of the collected sample. If sample analysis is delayed, the sample must be preserved to a pH <2 with hydrochloric (HCl) or sulfuric acid (H2SO4). All samples must be kept cool after collection (≤6°C). If it is suspected or known that the sample will contain a large concentration of extractable material (>500 mg/L), a smaller volume is appropriate. All samples collected for this analysis are grab samples. If a composite is required, additional volume in separate containers is necessary and the laboratory can perform the composite (whole volume collected) upon analysis. The regulatory hold time for the analysis is 28 days from the date and time of collection.

At the time of the Oil and Grease analysis, the laboratory verifies the pH preservation and will add additional acid if the pH is not <2. The Oil and Grease in the collected sample is extracted using n-hexane. The sample is transferred to a separatory funnel, receives 30 mL of n-hexane, mixed vigorously, and allowed to settle to let the organic and aqueous phases separate. The lower layer (aqueous layer) is drained into the original sample container, and the hexane layer remains in the separatory funnel. The hexane extract is drained through a funnel containing anhydrous sodium sulfate to remove any excess water from the extract and is collected in a pre-weighed container (flask or pan) to evaporate the hexane. The original sample goes through the process two more times to remove all Oil and Grease compounds for the analysis. Once the three extract portions are collected, the solvent is evaporated and the pre-weighed container is weighed to constant weight. The difference in mass is the amount of Oil and Grease in the collected sample.

To determine the Hydrocarbon portion of the Oil and Grease analysis, the sample is re-constituted with n-hexane. Silica gel is added to the sample in the ratio of 3 grams for every 100 mg of hexane extractable material. Once mixed, the slurry is filtered, and the filtrate is heated to evaporate the hexane to leave behind the Hydrocarbon fraction in a pre-weighed vessel.

In order to improve laboratory efficiency by automating this analysis, Caltest has two extraction systems developed by Horizon Technology (SPE DEX 3000XL). The system utilizes Solid Phase Extraction (SPE) to sorb the oil and grease compounds, and elute the sorbed compounds using methanol.

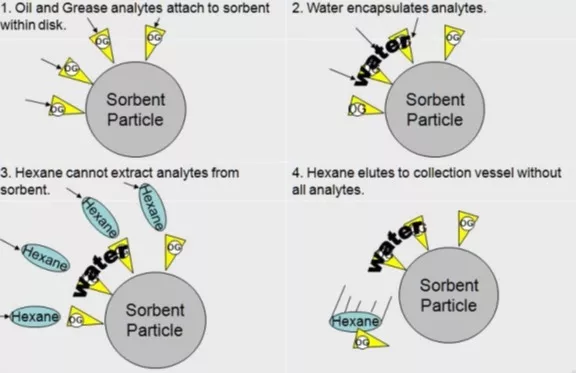

Figure 1. SPE molecular-level processes (from Horizon Technology).

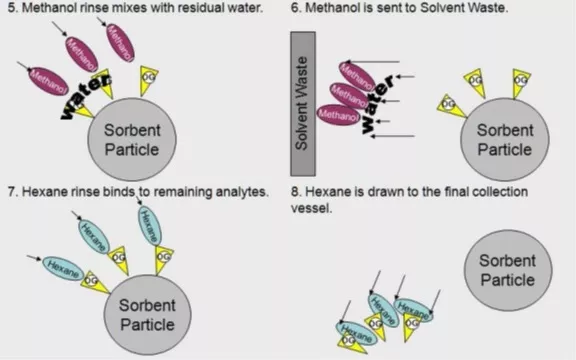

Figure 2. Elution process at a molecular level (from Horizon Technology).

This automated process reduces the volume of solvent used in the extraction process, and therefore reduces hazardous waste. The reduced volume of solvent also improves the safety for the analyst. Additionally, the likelihood of emulsions forming is eliminated, reducing the variability and speeding completion of the extraction step.

Environmental Protection Agency (EPA). 1999. Method 1664, Revision A: N-Hexane extractable material (HEM; Oil and Grease) and Silica Gel Treated n-hexane extractable material (SGT-HEM; Non-Polar Material) by Extraction and Gravimetry. EPA-821-R98-002. Office of Water, Washington, DC.

EPA. Oil and Grease: Questions and Answers. Last updated September 12, 2013. Available online at http://water.epa.gov/scitech/methods/cwa/oil/oilfaq.cfm

Hamel, M., and J. Fenster. Maintainng regulatory method compliance while automating oil and grease analysis. Horizon Technology, Salem, NH. Available online at: http://www.horizontechinc.com/PDF/white papers/Maintaining Regulatory Method Compliance while Automating Oil and Grease Analysis-Long (3).pdf

For more information, or a quote, please call us or email info@caltestlabs.com